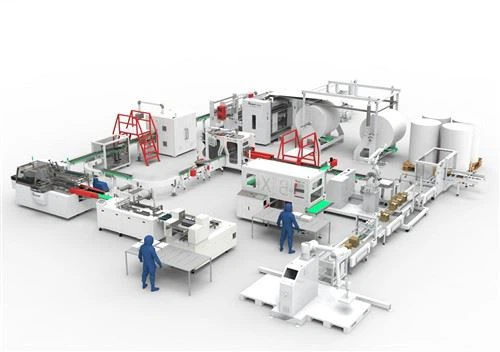

In the world of hygiene and cleanliness, wipes have become indispensable in homes, hospitals, and virtually everywhere. Their production hinges on sophisticated equipment designed to meet high standards of efficiency and reliability. Among the leaders in this industry, Onepaper stands out with its state-of-the-art manufacturing solutions. Let us delve into the mechanics of various wipes making machines, including wet wipes making machine, cotton towel making machine, and alcohol swab making machine, to grasp how they operate for optimal performance.

At the heart of wipes production is the wipes making machine, a marvel of engineering designed to produce high-quality wipes with precision and speed. These machines are equipped with advanced technologies that allow for the automation of various processes, including folding, cutting, and wetting. The ultimate goal is to produce wipes that are not only soft and durable but also saturated with the right amount of liquid solution, be it water for wet wipes or alcohol for disinfecting swabs.

Wet wipes have become a staple in personal and household cleaning routines. The wet wipes making machine is specifically engineered to infuse soft, absorbent nonwoven fabric with sanitizing or cleaning solutions. Efficiency in the production process is achieved through an integrated system that blends the liquid formulation, applies it evenly to the fabric, and ensures that each wipe is cut and folded to perfection. This machinery must also maintain the moisture content of the wipes from production till packaging to prevent drying out, signifying the importance of precision in its operation.

For applications requiring a touch of comfort and superior absorbency, cotton towels stand out. The cotton towel making machine specializes in producing towels that cater to these needs. Through a series of calibrated processes, this machine weaves, cuts, and folds cotton fabrics into luxurious towels. The intricate mechanics involve controlling texture and absorbency levels, showcasing the machine's ability to customize production according to varying specifications.

In medical and critical hygiene contexts, alcohol swabs are indispensable. The alcohol swab making machine is designed for the precise impregnation of cotton or nonwoven fabric with alcohol-based solutions. The critical challenge for this type of machine is to ensure that each swab is saturated with a controlled quantity of alcohol for effective disinfection. The machinery achieves this through meticulous metering and application systems, highlighting the importance of accuracy in the production of medical-grade wipes.

Achieving optimal performance in wipes production entails more than just advanced hardware. It requires an understanding of the interplay between material properties, liquid formulations, and machine settings. Onepaper’s range of equipment is built with this holistic view in mind, ensuring that every aspect of the production process is optimized for quality and efficiency. From precise moisture control in wet wipes making machines to the delicate balance of softness and strength in cotton towel making machines, every detail is fine-tuned.

The mechanics behind wipes making machines are both complex and fascinating. They embody a blend of engineering excellence and technological innovation aimed at meeting the growing demand for hygiene products. With companies like Onepaper at the forefront, the industry is well-equipped to continue delivering products that play a crucial role in maintaining cleanliness and health standards worldwide. Whether it’s a wet wipes making machine, cotton towel making machine, or alcohol swab making machine, the focus remains on optimizing performance to produce high-quality wipes that cater to diverse needs.