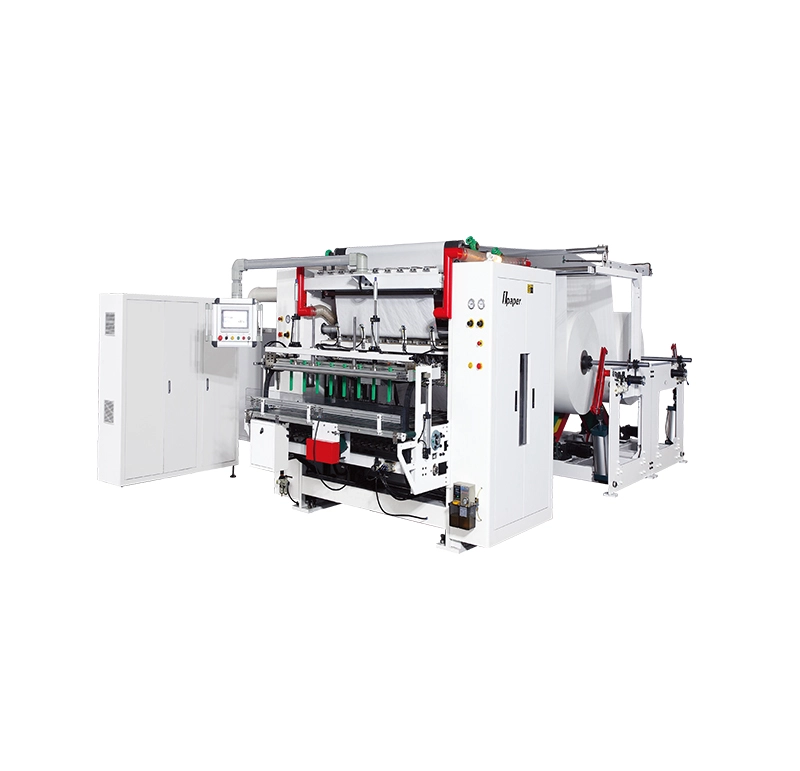

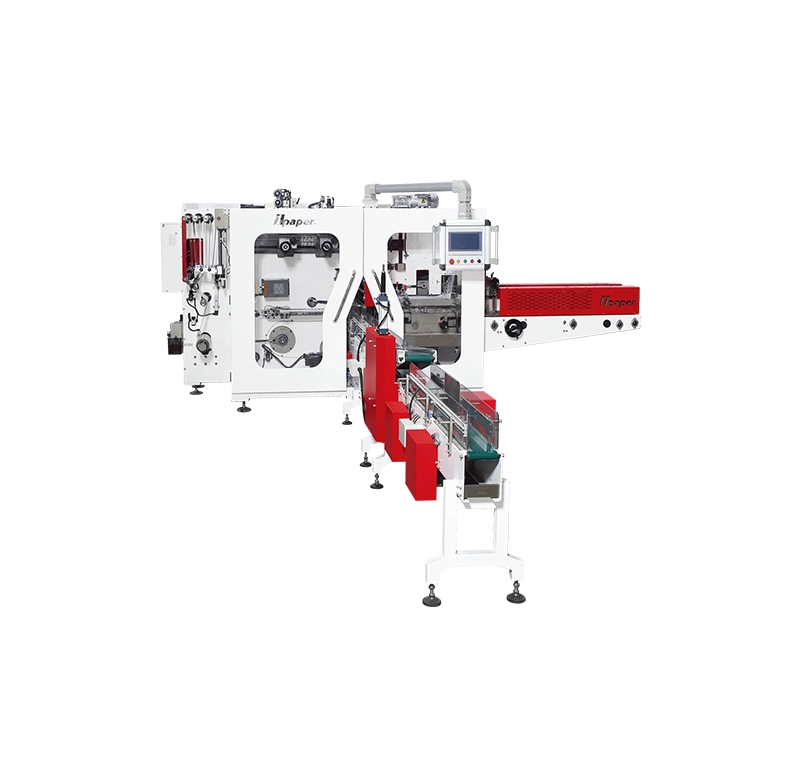

Onepaper tissue paper making machines are engineered for excellence, featuring advanced automation and state-of-the-art technology. This ensures high-speed production without compromising on quality, enabling businesses to meet market demands swiftly and effectively.

Emphasizing sustainability, Onepaper machines are designed to minimize waste and reduce energy consumption. Their innovative use of recycled materials and efficient processing techniques supports eco-friendly production practices, aligning with global environmental standards.

Understanding the diverse needs of the tissue paper industry, Onepaper offers highly customizable machines. This flexibility allows for the production of a wide range of tissue paper products, from standard to premium quality, catering to specific market requirements and enhancing product competitiveness.

Navigating the global market for tissue paper making machines requires a keen understanding of both technological advancements and regional market demands. As international business expands, manufacturers and suppliers of tissue making machinery must adapt to diverse requirements, ranging from environmental regulations to production capacity preferences. The global landscape presents a myriad of opportunities for businesses willing to innovate and cater to a broad spectrum of needs, solidifying their position in the competitive market for tissue paper making machines.

For instance, in regions with stringent environmental laws, the demand for tissue making machines that support eco-friendly production processes, such as those capable of processing recycled fibers or reducing water and energy consumption, is on the rise. Meanwhile, emerging markets with growing consumer bases may prioritize tissue making machines that offer scalability and high-speed production capabilities to meet increasing demands.

Moreover, the integration of digital technologies into tissue paper making machines is becoming a universal requirement. Features like real-time monitoring, predictive maintenance, and automation are sought after for their ability to enhance efficiency, reduce downtime, and ultimately, lower production costs. These technological advancements not only improve the operational aspects of tissue paper production but also contribute to the production of higher quality products, elevating the value proposition of tissue paper machine for sale in the global market. Similarly, the wet wipes production machine is also benefiting from the integration of advanced digital technologies. These machines are now equipped with features such as real-time monitoring, which allows operators to track the production process and make adjustments on the fly to ensure optimal performance.

To successfully navigate the global market, manufacturers must remain agile, continuously innovating to meet the evolving needs of different regions. This involves not only the adaptation of machine designs and features but also a commitment to after-sales support and service, ensuring that clients worldwide can maximize the potential of their tissue paper making machines.